AEM Hydrogen Plant Gas Generator

Product Introduction

- Water H2O + Power = Hydrogen H2 (+ Oxygen O2)

- Working pressure (according to technology) Up to 10-20 bar

- Hydrogen production Up to 50Nm3/h

- Gas purity with purification system : 99.7% ± 0.2%

- (Water saturated)

- After purification Up to 99.999%

Why choose us ?

1

Provide one stop solution for customized hydrogen generating equipment and service.

2

Rich experience in Hydrogen engineering and plant based equipment fabrication & supply.

3

Experienced experts in H2 related field to learn and do customer demand analysis.

4

Professional team with

expertise for overseas project management.

5

Experience with European and American Pioneer in Hydrogen Industry.

H2 Generator

System Integration

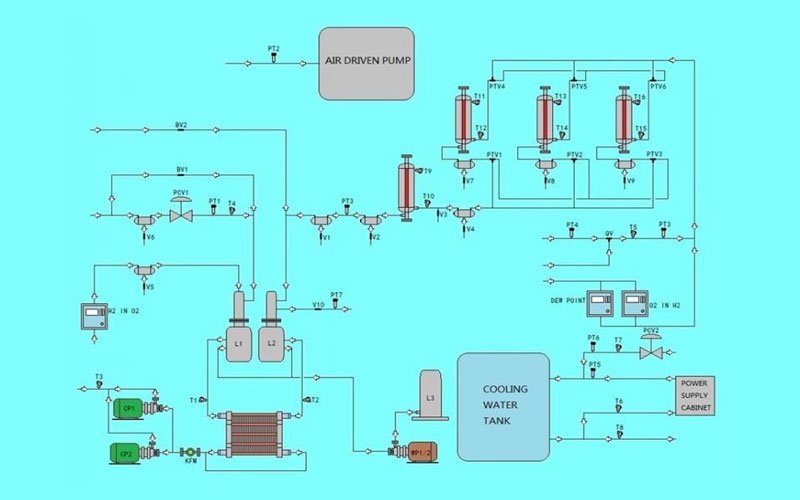

- H2 produces by Electrolysis Technology to produce UHP Hydrogen Gas from H2O

High Reliability

- High Reliability

- Optimized design to ensure the excellent quality

Cost Saving

- Low operation cost 7 x 24 Continuously running

Easy for Operation

- Optimised structure

- Compact design

- Plug and play

Intelligent Control

- Intelligent evacuation of unqualified Hydrogen to realize unattended

Unique Material Selection

- Adsorption canister uses astronautics sophisticated aluminum profile

ELECTROLYZER - CELL

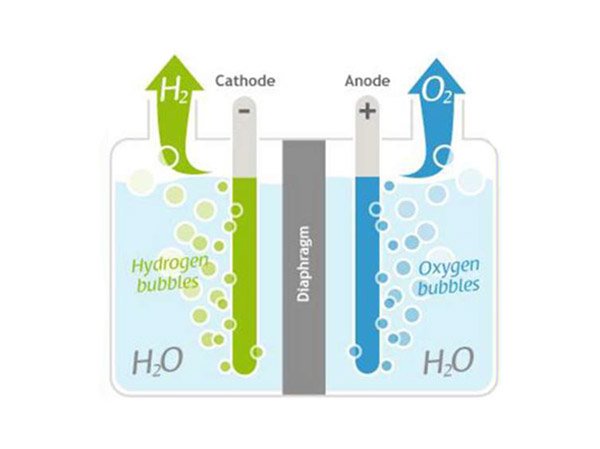

Electrolytic Cell, we apply bipolar technology, special

material polar frame, non-asbestos membrane cloth and

low cost electrode for electrolysis cell. our major material

for electrode is nickel. H2 will be evolved on cathode side of

cells and O2 will be evolved on the anodes of cells at the

same time.

H2/O2 Separator, H2 and O2 come separately into H2

separator, where they are cooled by cooling water and

separated from the mixture of gas-lye. after that H2 is

cooled by coil-piped cooler which is erected in the washer.

final H2 flows into hydrogen drying unit for further

purification. O2 process will be same as H2 process.

H2 Separation and Purification Unit

- Compact design w/SS frame

- SS316L pipeline

- Lye cooler SS 316L applied

- ASME, PED standard available

- Separation and purification Skid with SS material

Dry unit

- Three tower design

- Zero consumption of regeneration

| MODEL | (Nm3/h) H2 Capacity | (Nm3/h) O2 Capacity | H2 Purity | (A) Current | (V) DC Voltage | Cell Working Temp | Total Water Consumption | Total Power Consumption | Cooling Water Consumption |

|---|---|---|---|---|---|---|---|---|---|

| ATH-5S | 5 | 2.5 | 99.999% | 250 | 100 | <80°C | 5 L/hr | 27 Kw*h | 4 m3/h |

| ATH-10S | 10 | 5 | 99.999% | 250 | 200 | <80°C | 10 L/hr | 52 Kw*h | 6 m3/h |

| ATH-15S | 15 | 8 | 99.999% | 960 | 78 | <80°C | 15 L/hr | 78 Kw*h | 10 m3/h |

| ATH-20S | 20 | 10 | 99.999% | 960 | 90 | <80°C | 20 L/hr | 105 Kw*h | 12 m3/h |

| ATH-30S | 30 | 15 | 99.999% | 960 | 156 | <80°C | 30 L/hr | 155 Kw*h | 12 m3/h |

| ATH-50S | 50 | 25 | 99.999% | 960 | 260 | <80°C | 50 L/hr | 260 Kw*h | 18 m3/h |

| ATH-75S | 75 | 38 | 99.999% | 960 | 392 | <80°C | 75 L/hr | 382 Kw*h | 18 m3/h |

| ATH-100S | 100 | 50 | 99.999% | 3000 | 168 | <80°C | 100 L/hr | 512 Kw*h | 18 m3/h |

| ATH-150S | 150 | 75 | 99.999% | 3000 | 252 | <80°C | 150 L/hr | 764 Kw*h | 20 m3/h |

| ATH-200S | 200 | 100 | 99.999% | 3000 | 334 | <80°C | 200 L/hr | 1012 Kw*h | 20 m3/h |

| ATH-250S | 250 | 125 | 99.999% | 3000 | 400 | <80°C | 250 L/hr | 1212 Kw*h | 20 m3/h |

| ATH-300S | 300 | 150 | 99.999% | 3000 | 501 | <80°C | 300 L/hr | 1515 Kw*h | 25 m3/h |

| ATH-400S | 400 | 200 | 99.999% | 7300 | 700 | <80°C | 400 L/hr | 2115 Kw*h | 25 m3/h |

| ATH-500S | 500 | 250 | 99.999% | 7300 | 343 | <80°C | 500 L/hr | 2520 Kw*h | 30 m3/h |

World leading technology

High effciency / Low consumption

Reliable performance

Solid quality & performance